According to VisIC Technologies, VisIC unveils new 8mOhm power switch for EV Inverters

Designed for EV, the high power D3GaN 8mOhm product for high voltage and high current Inverter applications brings higher efficiency and smaller size

– Low Ron power GaN switch based on D3GaN technology for the EV market

– The new solution designed specifically for the EV Inverter application

VisIC Technologies Ltd., a global leader in gallium nitride (GaN) devices for automotive high-voltage applications, is proud to announce its new low resistance product for EV Inverter application that will improve efficiency and manufacturing cost of electric cars. The new 8mOhm product is another step in the ongoing effort to support our customers and improve the power conversion systems.

“The V8 product doubles the current capabilities and reduces resistance by a factor of 2.5 times over the previous generation of VisIC product. This will allow our customers to improve their inverter systems to be more efficient in size, power, and cost for the target EV market.” said Mr. Ran Soffer, VisIC SVP Sales & Marketing. “The V8 product is another step in our long-term effort to provide a better solution based on our D3GaN technology. The work on the new product is done in close collaboration with our leading customers to bring meaningful improvement to the electric drive system which is the heart of the Electrical Vehicle. The higher power density can also be achieved in high-power traction invertors”, added Mr. Ran Soffer.

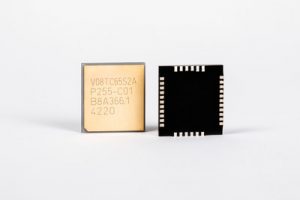

The new product is rated at 8mΩ, 650V, 200Amp and provides significantly lower switching losses versus comparable IGBT or SiC devices for the same current range. Customers can integrate the new die into both discrete packages and power modules with a variety of interconnect options. This new technology enables power loss savings particularly in drive cycle tests for high current Electric Vehicle inverter systems.

The challenge of manufacturing a single die with a high current is a known challenge for wide band gap technologies (WBG), such as SiC and GaN, vs ubiquitous Silicon dies. The breakthrough of 200A GaN dies has been made possible due to the thoughtful design of the D3GaN platform and manufacturing excellence of TSMC, the manufacturing partner of VisIC company. This breakthrough will enable Electric Vehicles to benefit from the high-efficiency technology of GaN. This will lead to more cost-effective EV cars, for a greener and cleaner planet.

This press release and further information can be found at www.visic-tech.com

SOURCE VisIC Technologies